Новини світу мікро- та наноелектроніки

Axcelis launches Purion Power Series+ ion implant platform for SiC power devices

Keysight Introduces Physical Layer Compliance Test Solution for HDMI Links

Enphase Energy opens US pre-orders for its first GaN-based microinverters

Infineon signs memorandum of understanding with China’s Lingji

Calculation of temperature from PRTD resistance

I recently contributed a design for a simple platinum resistance temperature detector (PRTD) resistance two-wire 4-20mA transmitter circuit illustrated in Figure 1.

Figure 1 A two-wire, 4 to 20 mA current loop PRTD transmitter with 500 µA constant current sensor excitation. R1 and R2 are 0.1% tolerance, voltage reference is a 2.5-V LM4040x25

Wow the engineering world with your unique design: Design Ideas Submission Guide

Analog to digital conversion of the 4 to 20 mA Io reading is likewise simple and straightforward (a 250-Ω shunt resistor at the input of a 0 to 5-V ADC of adequate resolution and precision will do nicely) and getting from there to Rprtd is an easy chore in software (Io in milliamps):

PRTD resistance = R1(Io/Ix – 1) = 20Io – 10

The final step from there to a linear temperature measurement would be almost equally easy, thanks to Callendar Van Dusen (CVD) math, except for one annoying detail. The famous CVD polynomial is arranged to calculate PRTD resistance from temperature. Unfortunately, what we need is temperature from resistance!

Fortunately, another classic algebraic expression can ride to our rescue: The Quadratic Formula (QF).

Mixing vigorously CVD and QF and defining two constants:

u = 0.0039083 RPRTD@0oC

w = -0.0000005775 RPRTD@0oC

and one new variable,

x = RPRTD@0oC – PRTD

leads to a straightforward polynomial that will directly calculate a PRTD temperature from PRTD resistance that’s linear to within ±0.05oC over a temperature range spanning -80oC to +850oC.

ToC= (-u + (u2 – 4wx)1/2)/(2w)

Stephen Woodward’s relationship with EDN’s DI column goes back quite a long way. Over 100 submissions have been accepted since his first contribution back in 1974.

Related Content

- Simple but accurate 4 to 20 mA two-wire transmitter for PRTDs

- A two-wire temperature transmitter using an RTD sensor

- Improved PRTD circuit is product of EDN DI teamwork

- The power of practical positive feedback to perfect PRTDs

- Hotwire thermostat: Using fine copper wire as integrated sensor and heater for temperature control

The post Calculation of temperature from PRTD resistance appeared first on EDN.

Electronica India 2025: “It isn’t about browsing gadgets, it’s about validating million-dollar CapEx and OpEx decisions with live demonstrations,” says CEO Bhupender Singh

India’s electronics and semiconductor sector is at an inflection point. With government-backed incentives like the Production Linked Incentive (PLI), Electronic Components Manufacturing Scheme (ECMS), Design Linked Incentive (DLI) schemes, global supply chains realigning toward India, and domestic demand projected to propel the industry to US$500 billion by 2030, the country is rapidly shifting from a consumption-led market to a global hub for innovation, manufacturing, and IP creation.

At the heart of this momentum are platforms like electronica India and productronica India, organized by Messe Muenchen India. Far more than trade shows, these events have evolved into strategic accelerators of industry growth. By convening policymakers, global investors, innovators, suppliers, and manufacturers under one roof, they drive not just dialogue but measurable outcomes—new partnerships, technology transfers, integrated supply chains, and policy-to-market translation that strengthen India’s electronics value chain.

In this exclusive conversation with the ELE Times, President IMEA (India, Middle East, Africa), Messe München, CEO, Messe Muenchen India, shares his vision of how these platforms are turning India’s complexity into opportunity. From conceptualising the India Semiconductor Conclave to expanding into dual editions across North and South India, Mr. Singh outlines how electronica India and productronica India are catalyzing India’s transition from a promising market to a first-choice global electronics manufacturing hub. His insights reflect not only the growth of the two pioneering exhibitions but also the story of a nation positioning itself at the centre of the world’s electronics and semiconductor future.

- Since electronica India and productronica India began in 2000, what do you see as the biggest missed opportunities in their India journey—and how are you ensuring those opportunities are now fully realized?

In many ways, electronica India and productronica India have been a true barometer of India’s electronics industry. Over the years, as the Indian industry navigated the electronics design, services, and manufacturing industries from inverted tax structures to duty-free components and the current push for semiconductors and passive components self-reliance, these shows have consistently highlighted the trending opportunities supporting the Indian industry’s requirements.

While India’s exponential growth and the rapid evolution from being a talent pool to a design and manufacturing powerhouse were faster than expected, it did attract global players who recognized India’s potential. We are capitalising on this opportunity by curating platforms that connect policy makers, investors, innovators, suppliers, and manufacturers under one roof. Through initiatives such as the India PCB Tech Conference, CEO Forum, etc., and stronger global partnerships, we are converting that complexity into structured opportunity.

These events are not just exhibitions; they are essential hubs driving dialogue, enabling policy alignment, and facilitating high-value business partnerships critical to India’s electronics roadmap.

- What is your vision for electronica India and productronica India in the next 5-7 years, and what concrete milestones will you use to measure whether that vision is being achieved?

Our vision is anchored in India’s national target of US$500 billion in electronics manufacturing by 2030. We firmly believe in supporting this goal and are confident that our shows will act as catalysts for this journey—not just by providing visibility but by accelerating deal-making, knowledge exchange, and policy adoption.

To achieve our vision and in a move that marks a strategic turning point for India’s electronics manufacturing sector, we are rolling out a two-edition model—annual editions of electronica India and productronica India in both Delhi-NCR and Bengaluru. Each of these regions has its own unique ecosystems, and the new format responds to clear industry demand: shorter sourcing cycles, stronger regional access, and more consistent face-to-face engagement.

Through these region-focused shows, we look to transform India from being primarily a consumption market to becoming a global hub for innovation, manufacturing, and IP creation. The shows are designed as confluences of ideas—where roadmaps are stress-tested, sourcing strategies redesigned, and partnerships sealed. Success will be measured across four milestones:

- Business Outcomes – Tangible trade volumes and partnerships generated through the shows.

- Global Participation – More Tier-1 semiconductor and electronics majors co-locating their R&D and design centres in India.

- Policy Engagement – Using the platform to bridge government missions with industry stakeholders.

- Sustainability impact – Where exhibitors demonstrate measurable progress on green manufacturing.

- electronica India is often called a symbol of India’s technological strength. Beyond scale and visibility, what makes the show truly competitive against global giants like CES or Computex?

electronica India and productronica India began over two decades ago as focused B2B trade platforms. Today, they’ve evolved into the country’s largest integrated events for electronic components, systems, applications, and production technologies. While the comparison with CES or Computex is flattering, the differentiation is clear. Those are consumer-tech showcases, and electronica India and productronica India are ecosystem shows from the ground up—focused on components, design, production, and manufacturing solutions.

Our competitive edge lies in our ability to align India’s electronics strengths with global supply-chain needs while creating an authentic “design-to-manufacture” narrative. It lies in the deep dive systems view we offer from semiconductors and embedded systems to SMT automation, inspection, EMS, and supply-chain solutions.

For decision-makers, this is not about browsing the future of gadgets; it’s about validating million-dollar CapEx and OpEx decisions with live demonstrations. Our shows are centre points where product roadmaps are stress-tested, sourcing strategies redesigned, and partnerships get inked.

Moreover, the shows are dual-purpose: fulfilling the domestic market’s aspirations while positioning India as a credible export and services base. This unique two-front approach—local growth with global integration—makes them competitive with, and in some ways complementary to, the world’s largest technology platforms.

- You’ve announced that electronica India and productronica India will now be held twice a year. Isn’t there a risk of diluting quality or splitting participation? How will you prevent electronica India and productronica India from becoming just another crowded trade show?

The fear of dilution is natural, but the reality is different. India’s electronics industry is expanding so rapidly that one annual event can no longer serve its needs. Due to our shows taking place only once in two years in each region, 80% of our buyers visited only local shows, due to which they were facing significant sourcing gaps. They were pleased to support the dual-edition approach because it allows them to target regional clusters, send larger teams, and gain sharper insights.

Similarly, 70% of our top buyers felt that this was the way forward to create sharper industry fulfilments, and it meant easier access without waiting two years for the platform to return to their region or traveling across the country.

With exhibitor numbers growing year on year, two shows will mean a more expansive platform to enable us to cater to the entire industry across verticals and categories.

We don’t see this as two smaller shows. We see it as a distributed national platform. Quality will be preserved through strict curation, serious exhibitors, targeted buyers, and knowledge-driven conferences. Instead of spreading thin, we are going deeper, closer to where the industry is growing.

Our role is not just to mirror market shifts but to actively shape the ecosystem by fostering collaborations that lead to tangible outcomes.

- India’s electronics manufacturing has grown rapidly, but critical areas like advanced semiconductors and IP creation still lag. How do electronica India and productronica India plan to attract global leaders in these domains rather than just showcasing assembly strength?

The challenge is not just manufacturing scale—it’s moving up the value chain. To bridge this, we are positioning electronica India and productronica India as knowledge-driven hubs.

We are focusing on knowledge partnerships and high-level policy dialogues to make India a dependable choice for global majors. Initiatives such as the e-Future Conference, the Smart Factory Innovation Conference, the India Semiconductor Conclave, and many more are curated specifically to attract global chipmakers, fabless design firms, and equipment suppliers to engage with India’s policy-makers and startups. It’s not about showcasing assembly strength; it’s about sparking IP creation and R&D investments.

By presenting live case studies, early-stage MoUs, and collaborative projects, we aim to send a clear signal: India is serious about semiconductors, and now is the time for global leaders to place their bets here.

- With India’s electronics growth driven largely by government incentives, how does electronica India and productronica India see its own role—as policy influencer, industry catalyst, or bridge to global investors?

We are all three. Government incentives create momentum, but unless they are translated into execution, their impact is limited.

- As a policy influencer, we host closed-door roundtables where industry challenges directly inform government priorities.

- As an industry catalyst, we enable knowledge transfer and create forums for startups, MSMEs, and global giants to collaborate.

- As a bridge to investors, we bring global capital face-to-face with India’s electronics ecosystem.

The true value of these shows lies in being the intersection point where policy intent, industry capacity, and investor confidence converge.

- Many exhibitors today are ROI-driven. What hard evidence can you present to prove that participation at electronica India and productronica India translates into business growth and not just visibility?

We track ROI rigorously, and the data speaks clearly. In 2024, over 70% of exhibitors reported promising agreements and serious leads. Similarly, SMEs closed technology transfer agreements, while larger corporates expanded supplier networks.

The electronica India and productronica India growth trajectory is equally telling, with participation numbers rising year on year. From 325 exhibitors in 2022 to 839 exhibitors in 2024, we have come a long way. This is a clear indicator of the exhibitors’ gains, encouraging them to return to our shows year on year.

Beyond deals, the shows deliver strategic ROI: direct access to policymakers, visibility with investors, increased brand awareness, and insight into emerging market intelligence. In a sector where supply-chain decisions lock in for years, those conversations are invaluable.

- With global supply chains undergoing overhaul changes, how can electronica India and productronica India position India as a genuine hub for electronics innovation and manufacturing, rather than merely a fallback option?

By providing evidence of India’s resilience, scalability, and talent depth. Through partnerships showcased at our events, the shows highlight India’s evolution beyond the “China+1” narrative to becoming a first-choice hub.

On the show floor, visitors see the future in action: modular automation, smart pick-and-place systems, automotive-grade board protection, energy-efficient reflow technologies, and MES-ERP integrated traceability stacks. These aren’t just demonstrations—they are proofs of capability that global buyers need to see before committing to India.

At the same time, startups and MSMEs bring grassroots innovation, while global OEMs demonstrate scale and reliability. The combination tells the world that India is not just supplying today—it is prototyping tomorrow.

- Is electronica India and productronica India’s vision to focus on fewer genuine, high-value participants or on sheer numbers, and how will you ensure quality isn’t diluted?

Our goal comprises depth and scale. In fact, the numbers present a clear picture as to why our shows are very well balanced in terms of quantity and quality. We not only attract return exhibitors but also new exhibitors year on year.

In 2022, we welcomed 20,942 visitors who interacted with 325 exhibitors. In 2023, we saw 39,133 visitors connect with 600 companies, and in 2024, over 45,532 visitors met with over 839 companies from 29 countries.

And in 2025, we are looking at an unprecedented 60,000 sqm of space hosting over 850 exhibitors from 50 countries, showcasing 6,000+ products and solutions. With 2,000+ curated B2B meetings sitting buyers and suppliers across the table with pre-matched interests, our shows are engineered for outcomes.

While visitor numbers will naturally rise with India’s booming electronics sector, our curation will focus on qualified buyers, decision-makers, and technology leaders. We invest heavily in hosted buyer programs, matchmaking tools, and pre-scheduled meetings, ensuring deal-focused interactions.

In a landscape where supplier decisions lock in multi-year costs, those hours are highly leveraged where every interaction has business value.

- Finally, what is your key message to the visitors and participating brands this year—and what specific commitments are you ready to make to them?

My message is simple: electronica India and productronica India 2025 are not just exhibitions—they are growth accelerators.

We are committed to delivering:

- Business-ready leads through curated matchmaking and buyer forums.

- Knowledge leadership through world-class conferences and global experts.

- Policy access, giving industry participants a direct voice in shaping India’s electronics future.

Every participant, whether a startup or a multinational, should leave with something tangible: a lead, a partnership, or a policy connection. We promise to make the 2025 editions not just the stage for India’s electronics growth, but the engine that powers it forward.

The post Electronica India 2025: “It isn’t about browsing gadgets, it’s about validating million-dollar CapEx and OpEx decisions with live demonstrations,” says CEO Bhupender Singh appeared first on ELE Times.

Scintil raises $58m to scale integrated photonics for AI factories

Top 10 Decision Tree Learning Frameworks

In machine learning, a decision tree learning framework is a method that is used to generate predictions from the data. The outcomes of the decision process are represented as leaf nodes in a tree-like structure. A tree node corresponds to a particular feature, while the branches correspond to the decision rules. Having arrived at the leaf nodes, an example is assigned an output by the framework. This framework is used for classification (like the prediction of categories) and regression (like the prediction of number values).

How Does the Decision Tree Learning Framework Work:

The algorithm starts with choosing the most appropriate feature to divide the dataset. The choice is made on the basis of factors such as Information Gain, Gini Impurity, or Entropy. The data is divided into subsets on the basis of the chosen feature. It is performed recursively over each subset until a condition of stopping is reached such as the achievement of maximum depth or pure leaf nodes. The outcome is a tree in which every root-to-leaf path is a decision rule.

Decision Tree Learning Framework Examples:

Decision tree learning is a well-known algorithm in machine learning for classification and regression. Libraries such as Scikit-learn, XGBoost, LightGBM, Spark MLlib, and rpart (in R) implement decision trees with ease. They are used in situations such as customer behavior prediction, disease diagnosis, loan approval, and spam detection where a decision is taken by dividing data along feature boundaries until a conclusion is derived.

Top 10 Decision Tree Learning Frameworks:

- TensorFlow Decision Forests

This framework brings decision tree models to the TensorFlow ecosystem. It addresses those wanting to work with tree-based models combined with deep learning workflows or for deployment of models in production through TensorFlow Serving.

- XGBoost

Short for “Extreme Gradient Boosting,” XGBoost is the one for structured data. This method builds ensembles of decision trees using gradient boosting and is apt for speed, regularization, and prowess on Kaggle competitions.

- Scikit-learn

The Python software library for machine learning, Scikit-learn, provides an elegant and intuitive implementation of decision trees using the CART algorithm. It is well suited for both beginners and experts, providing excellent documentation and the ability to integrate with other Python tools.

- LightGBM

By Microsoft, LightGBM is focused on speed. It uses histogram algorithms and growing trees leaf-wise, which is faster and more memory-efficient than traditional gradient boosting techniques, especially on huge datasets.

- H2O.ai

H2O contains implementations of Random Forest, Gradient Boosting Machines, and so forth, and does so at lightning speed. It’s enterprise-ready, supports parallel processing, and includes a user-friendly web interface for model building and evaluation.

- Apache Spark MLlib

Spark MLlib has been designed with distributed computing in mind, which means it supports scalable decision tree learning on clusters. This makes it ideal in big data environments, tightly integrated with the rest of the Spark ecosystem for complementary data processing.

- RapidMiner

This platform is more geared towards non-programmers, providing drag-and-drop capabilities for decision tree modeling. It is mostly commonly used for business analytics and supports integration with Python and R for more advanced users.

- WEKA

WEKA, a Java-based toolkit, is mostly used within academic fields for teaching and research. It provides a graphical user interface along with a number of machine learning algorithms, including decision trees, thus easing experimentation and visualization.

- CatBoost

Created by Yandex, CatBoost is one of the really few methods that can operate on categorical variables without transforming them into some numerical version. Because it is so robust now, quite accurate, and seldom requires extensive tuning, it has become a go-to method used in many real-world business cases.

- Orange

A visual programming toolkit for data mining and machine learning which contains decision tree learners, Orange is ideal for prototyping and academics. Its modular nature permits users to assemble workflows interactively without any form of programming.

The post Top 10 Decision Tree Learning Frameworks appeared first on ELE Times.

A little ehile ago I posted my very first Kicad designed morpho shield for stm32 nucleo microcontroller. Well, heres the final!

| Hello everyone. This is the PCB I came up with. Its to simplify the setup of certain hardware laboratories controllers that I also came up with previously. Took me couple of days (around 4-5 hrs) of work to solder them all 40 boards. But this will make super easy to connect things, or replace the microcontroller in case of a failure. As my very first design (this is slightly revamped to add small "window" to see the status LED's on nucleo board), I once again, feel really proud, haha. The revamp also added another 6 blank pins for future expansion (there are plans to add dynamixel robot arms to controllable devices repertoire). [link] [comments] |

A digital technique eliminates the need for an analog multiplier

Traditionally, multiplying two analog signals involves the use of analog multipliers. Design engineers digitize analog signals using an analog-to-digital converter (ADC) and then run the code on a microcontroller to perform digital multiplication. However, another digital technique employing an XNOR logic gate alongside an ADC performs multiplication on two bitstreams, avoiding the cost of the analog multiplier.

Find out more about this substitute analog multiplication technique in an article published in EDN’s sister publication Planet Analog.

Related Content

- Simulating the front-end of your ADC

- Analog to Digital Converter (ADC) Basics

- Introduction to analog/digital converter (ADC) types

- Understanding analog-to-digital converter (ADC) drivers

- Analog-to-digital converter (ADC) accuracy in simple terms

The post A digital technique eliminates the need for an analog multiplier appeared first on EDN.

Reinforcement Learning Architecture Definition, Types and Diagram

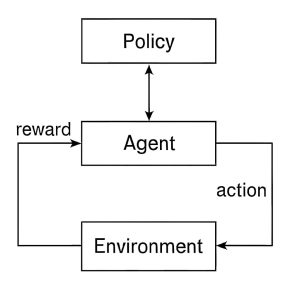

Reinforcement Learning is a type of machine learning in which an agent learns to act by interacting with an environment, performing actions, and getting feedback in the form of reward or penalty. Rather than being instructed what to do, the agent finds out the optimum strategy by trial and error, trying to maximize cumulative rewards in the long run. It alternates between exploration of novel actions and exploitation of familiar good ones, adjusts according to changing circumstances, and frequently faces delayed rewards requiring long-term planning.

Reinforcement Learning Architecture is founded on a constant feedback cycle between an environment and an agent. The agent reads the state of the environment, selects an action based on its policy (its strategy for making decisions), and applies it. The environment reacts by changing to a different state and issuing a reward or penalty. As time progresses, the agent alters its policy based on this feedback to optimize long-term cumulative rewards. Key components are the policy (how to select actions), the value function (predicting future rewards), and possibly an environment model for planning.

Main types of Reinforcement Learning:

- Policy-Based Reinforcement Learning

Policy-based approaches bypass the value function and learn a policy directly, i.e., a mapping from states to actions. These approaches are especially beneficial for use in high-dimensional or continuous action spaces. They learn the policy with methods such as gradient ascent. REINFORCE and Proximal Policy Optimization (PPO) are examples of popular algorithms used in this category, providing stability and training efficiency.

- Model-Based Reinforcement Learning

Model-based methods consist of creating an environment model that estimates the next state and reward based on a current state and action. The agent utilizes this model to reason about future consequences and decide its actions. This approach is potentially more sample-efficient than model-free methods. Some examples are Dyna-Q, which combines planning and learning, and Monte Carlo Tree Search, applied in game-playing agents.

- Actor-Critic Methods

Actor-Critic methods combine the advantages of value-based and policy-based approaches. The actor selects what action to perform, and the critic judges how well the action was chosen through a value function. Double structure diminishes variance and enhances learning stability. A3C (Asynchronous Advantage Actor-Critic) and DDPG (Deep Deterministic Policy Gradient) algorithms are most commonly applied in continuous control problems.

Reinforcement Learning Architecture:

The diagram depicts the basic structure of a reinforcement learning system, showing how an agent learns to behave optimally by interacting with its environment. At the top, the policy determines the agent’s choices by mapping states to actions. The agent, shown centrally, applies this policy to choose an action that it then performs in the environment. The environment responds with a reward given in feedback form, which is an indication of the success of the performed action. This reward is fed back to the agent so it can modify its policy and make better decisions in the future. The policy of cyclical flow from agent to agent, agent to environment through action, and environment to agent through reward perfectly describes trial-and-error learning characteristic of reinforcement learning. Gradually, this cycle enables the agent to improve its plan and achieve maximum cumulative rewards through ongoing interaction and learning.

The post Reinforcement Learning Architecture Definition, Types and Diagram appeared first on ELE Times.

Didn't have the correct SMD component, nor the pertinence to wait.

| Wanted to change the current limiting resistor on this DRV8871 motor driver board. Didn't want to wait for the correct component to used a through-hole resistor on 0603 pads. [link] [comments] |

Wolfspeed’s reorganization plan approved by court

Love pcbs like this

| I love seeing boards that have hidden messages or pictures on them [link] [comments] |

EEVblog 1707 - REPAIR: Goal Zero Yeti 400 Lithium Battery

Microchip Specializes GNSS Disciplined Oscillator Modules for Defense

Wise Integration appoints former Intel exec Ghislain Kaiser as CEO

CSA Catapult appoints Rupert Baines to board as non-executive director

QPT Ushers in AI-Ready GaN Motor Drives to Transform Cobots

Diagnosing a flickering LED light bulb

In my so-far nearly 30 years of writing for EDN, I’ve learned a lot about my ever-evolving audience (i.e., you), at least two aspects of which are directly relevant to this particular writeup:

- You love consuming any content that’s even remotely LED-related, and

- I’ve pretty much given up trying to figure out what topics will especially attract your attention, aside from relying on my own curiosity as a guide to what you might also like.

Take, for example, my recently published teardown of a LED-based desk lamp. Compared to some other teardowns that I’ve done, it was thankfully fairly speedy and straightforward to both implement and document. But, judging from the quantity and detail of the comments already posted on it, I’m guessing it’s still driving a lot of “eyeballs” to the EDN website. A fading-illumination-intensity-over-time LED apparently piqued more than just my curiosity.

The LED light bulb that transformed into a sorta-strobe lightOr take today’s dissection candidate, a conventional LED light bulb that had begun not fading, but instead, flickering. As historical background, I’ll take you back nine years to when I took apart my first LED light bulb, two dimmable examples of which had prematurely failed, due to (I prognosticated at the time) extended exposure to high temperatures caused by poor ventilation of the ceiling-mount enclosures within which they were installed. At the time, a reader named “docterdon” noted that I hadn’t described those sconces, so in the spirit of “a picture paints a thousand words”, here you go to start:

The room switch controlling the lights wasn’t dimmable anyway, so at the time I went ahead and replaced all of them (including the two still-functional ones, which I ended up reusing elsewhere) with CFLs. Two of those ended up prematurely dying too, so once again I swapped them out for LED bulbs, non-dimmable this time (I was admittedly surprised to realize, when recently reviewing past published teardowns, that in the plethora of LED-based illumination sources I’ve taken apart in recent years, a conventional non-dimmable one hadn’t yet gone under my knife). They came eight to a package; here’s the encompassing cardboard label:

Behind it in each initially shrink-wrapped assemblage, four of which my email archives indicate I’d promotion-purchased from VMInnovations back in October 2018 for $9.99 total, were two boxes, each with four bulbs inside (yes, your math is right; that translates to $0.31 per bulb!):

Here’s our flickering victim, as usual, accompanied by a 0.75″ (19.1 mm) diameter U.S. penny for size comparison purposes:

Shifting the bulb slightly to the left, here’s your reminder that my office desk is perpetually bathed by the light coming from—among other things—the front-panel blue (when the computer it’s connected to is powered on, that is; otherwise white) LED of the expansion hub tethered to my Mac mini, whose illumination you’ll see in some of the shots that follow:

Onward; let’s get the globe off. Extended exposure to my wife’s hair dryer didn’t help much with loosening the adhesive; then again, unlike what my heat gun had done in the past, it didn’t deform the globe itself, either. Nevertheless, using several “spudgers” and aided by plenty of “elbow grease” and “colorful language”, I finally wrestled the globe off the base:

Admittedly, in the process, snapping one of the three resistors off the plate, along with scraping the phosphor cap off one of the LEDs:

That large IC you see at center left is the RM9003T, a high-voltage single-channel constant current LED controller from Shaanxi Reactor Microelectronics. That said, from past experience, I strongly suspected that what I was currently seeing wasn’t the full extent of the circuitry; there was likely more behind the plate. There’s only one way to find out for sure:

At this point, my forward progress was stalled until…ah, yes, those power wires running to the cap end need to be disconnected before I can completely remove the plate. Time to dig out my tongue-and-groove, slip-joint (aka, “Channellock”) pliers and wrest it off…

At this point, my forward progress was stalled until…ah, yes, those power wires running to the cap end need to be disconnected before I can completely remove the plate. Time to dig out my tongue-and-groove, slip-joint (aka, “Channellock”) pliers and wrest it off…

That’s more like it:

The markings on the IC on one side of the now-exposed underside PCB:

are barely discernible:

MB6S

1607

It appears to be a miniature surface-mount bridge rectifier, converting (crudely) AC to DC in combination with the 390 kΩ (“394”) resistor next to it and the 200-V 10-µF aluminum electrolytic capacitor on the PCB’s other side:

Speaking of enclosed spaces with insufficient airflow and consequent overheating potential (generated by the multi-LED array on the plate above it), I’m guessing that here’s where the flickering originates. Agree or disagree, readers? Share your thoughts in the comments!

—Brian Dipert is the Editor-in-Chief of the Edge AI and Vision Alliance, and a Senior Analyst at BDTI and Editor-in-Chief of InsideDSP, the company’s online newsletter.

Related Content

- Teardown: What killed this LED bulb?

- The empty promise of the LED bulb’s lifetime

- Disassembling a LED-based light that’s not acting quite right…right?

- A brief history of the LED

- Freeing a three-way LED light bulb’s insides from their captivity

The post Diagnosing a flickering LED light bulb appeared first on EDN.