Новини світу мікро- та наноелектроніки

EPIR orders second Riber MBE 32 MCT research system

EPC presenting power solutions for automotive, robotics, power tools, solar at PCIM Europe

Semiconductor Mega Trends and Career Opportunities

The semiconductor industry is experiencing a profound transformation, propelled by technological advancements, market dynamics, and global initiatives. In India, this transformation is particularly significant, as the nation emerges as a key player in the semiconductor landscape. Let’s delve into the mega trends shaping the semiconductor industry in 2024, the career opportunities they present, and the role of the Electronics Sector Skills Council of India (ESSCI) in preparing professionals for this dynamic field.

Semiconductor Applications Across Diverse Fields:

Semiconductor chips serve as the fundamental building blocks powering a vast array of applications, wielding control over power management, enabling intricate power electronics systems, and orchestrating indispensable functions within electronic devices. From the ubiquitous smartphones and computers to the intricate network of IoT devices, semiconductor chips form the backbone, fuelling innovation and driving the seamless integration of technology into our daily lives.

- Driving Automotive Innovation: Semiconductor technology has spearheaded transformative advancements in the automotive sector, ushering in a new era of intelligent and dependable vehicles. By seamlessly integrating semiconductor components, automobiles have evolved to possess heightened intelligence, unparalleled reliability, and superior performance. Advanced Driver Assistance Systems (ADAS) rely on semiconductor solutions for critical features such as collision avoidance, lane departure warning, and adaptive cruise control.

- Revolutionizing Telecommunications: Semiconductor innovation is at the forefront of transforming the telecommunications landscape. With the emergence of 5G networks, semiconductor solutions are crucial for powering base stations, antennas, and network infrastructure, enabling faster data speeds, lower latency, and unparalleled connectivity. In addition to network infrastructure, semiconductor chips are integral to the development of smartphones, enabling advanced features such as AI-driven cameras, augmented reality, and facial recognition.

- Empowering Healthcare Technologies: Semiconductor technology is revolutionizing healthcare by driving advancements in medical diagnostics and patient care. Medical imaging devices, including MRI and CT scanners, heavily rely on semiconductor components for signal processing and image reconstruction, enabling precise diagnostics and treatment planning. Semiconductor chips also power medical monitoring devices such as wearable fitness trackers and smart health monitors, allowing for continuous health tracking and remote patient monitoring.

- Transforming Hearables and Wearables: The integration of semiconductor technology has led to remarkable advancements in hearable and wearable devices, revolutionizing the way we interact with technology. Hearables, such as wireless earbuds and smart headphones, leverage semiconductor chips for Bluetooth connectivity, noise cancellation, and audio processing, delivering immersive audio experiences. Similarly, wearable devices, including smartwatches and fitness trackers, rely on semiconductor solutions for sensors, data processing, and connectivity, enabling seamless health and activity tracking.

Career Opportunities in Semiconductor Technology:

As the semiconductor industry evolves in response to these mega trends, it creates exciting career opportunities for professionals across the value chain – designing, fabrication and packaging. From semiconductor design and manufacturing to research and development, there is a growing demand for skilled professionals who can innovate and drive technological advancements in the industry. The sector is expected to see more than 800,000 to 1 million job openings over the next five years, says staffing company Randstad. The government recently approved $15 billion worth of investments into the sector including from the Tata group. India’s burgeoning semiconductor sector is facing a surge in demand for talent, fuelled by new investments and the government’s ambitious plan to transform the country into a chip manufacturing hub.

- Semiconductor Design Engineer: Semiconductor design engineers play a crucial role in developing the architecture and circuitry of semiconductor chips. They utilize tools like Electronic Design Automation (EDA) software and simulation tools to design and optimize chip layouts for performance, power efficiency, and manufacturability.

- Process Engineer: Process engineers are responsible for developing and optimizing semiconductor manufacturing processes. They work closely with equipment vendors and manufacturing teams to ensure the smooth operation of semiconductor fabrication facilities, improve yield rates, and reduce production costs.

- Research Scientist: Research scientists in the semiconductor industry focus on exploring new materials, devices, and technologies to push the boundaries of semiconductor innovation. They conduct experiments, analyse data, and collaborate with cross-functional teams to develop next-generation semiconductor solutions.

- Material Engineers – Material engineers in the semiconductor industry are pivotal in researching, selecting, and optimizing the materials used in semiconductor device fabrication. Their expertise spans a wide range of materials, including silicon, gallium arsenide, and various compound semiconductors. Material engineers work closely with semiconductor design teams to ensure that the chosen materials meet the performance requirements of the intended applications while also considering factors such as cost, scalability, and reliability.

- Product Marketing Manager: Product marketing managers play a vital role in bringing semiconductor products to market. They conduct market research, develop marketing strategies, and collaborate with sales teams to promote semiconductor products and drive revenue growth.

- Quality Assurance Engineer: Quality assurance engineers ensure that semiconductor products meet the highest standards of quality and reliability. They develop and implement test plans, conduct performance testing, and analyse data to identify and address any issues or defects in semiconductor products.

- Packaging experts: Packaging experts in the semiconductor industry are instrumental in developing and implementing packaging solutions that safeguard semiconductor chips. Their role entails meticulous selection of packaging materials, designing efficient packaging structures to ensure protection against environmental factors and mechanical stresses, and optimizing designs for thermal management and electrical performance. They collaborate closely with design and manufacturing teams to ensure that packaging solutions meet stringent industry standards while balancing factors such as cost-effectiveness and manufacturability.

- Machine maintenance technicians –Machine maintenance technicians also play a crucial role in implementing preventive maintenance schedules, identifying opportunities for equipment upgrades or optimizations, and ensuring compliance with safety regulations and operational standards. Their expertise contributes to the overall efficiency and longevity of semiconductor manufacturing operations.

- Safety protocol checkers – These people are integral to maintaining a safe and secure work environment within semiconductor manufacturing facilities. They are responsible for enforcing safety regulations, conducting regular inspections to identify potential hazards, and implementing corrective measures to mitigate risks and prevent accidents. Safety protocol checkers also play a vital role in developing and implementing safety training programs, conducting safety audits, and promoting a culture of safety awareness among employees. Their diligence and vigilance help to safeguard the well-being of personnel, protect semiconductor manufacturing equipment, and maintain the integrity of semiconductor processes.

Qualifications: National Occupational Standards by ESSCI

As the field becomes more specialized, advanced degrees or skill training provide a competitive edge. Specialized qualifications like IC Package, VLSI Design, and Package Design enhance a designer’s expertise. As on date ESSCI has developed 25 NSQF aligned and approved qualifications on semiconductors (Design, Packaging & Manufacturing segment) and is also planning to develop more qualifications as per the need & demand of the industry especially on the Clean Room, Machine Maintenance and other related fragments, which are the need of the hour.

Short Term Qualifications & Upskilling NOS’s

ESSCI offers focused a range of qualifications covering the complete value chain of the semiconductor industry. Short Term courses such as VLSI Design Engineer, concentrating on designing SOC-module functions using software, Embedded Full Stack Engineer, IoT Hardware Analyst are some of the top courses offered for pursuing engineering graduates to gain the knowledge of EDA Tools and system design. ESSCI also provides qualifications for Wafer Back Grinding Engineer and Wafer Dicing Engineer, specialising in wafer manufacturing tasks which can be taught to ITI / Diploma students.

ESSCI also has foundation / upskilling courses in the field of Nano Science & Advance Nano Science which is also in great demand.

Also, there are some basic courses on the Industrial Safety – Electrical & Hazchem which are very crucial & important for the industrial safety requirements. The complete list of our qualifications along with their model curriculum are all uploaded on our website – https://essc-india.org/qualification-packs.php In conclusion, the semiconductor mega trends present unprecedented opportunities for India to assert its leadership in the global semiconductor industry. Through strategic investments, policy support, and talent development initiatives, India is poised to capitalize on these trends, driving innovation, fostering entrepreneurship, and creating a thriving semiconductor ecosystem for generations to come.

Dr. Abhilasha Gaur, Chief Operating Officer

Dr. Abhilasha Gaur, Chief Operating OfficerElectronics Sector Skills Council of India

The post Semiconductor Mega Trends and Career Opportunities appeared first on ELE Times.

Vishay Intertechnology 600 V E Series Power MOSFET in Compact Top-Side Cooling PowerPAK® 8 x 8LR Delivers Industry’s Lowest RDS(ON)*Qg FOM

Fourth-Generation Device Enables Higher Power Ratings and Density Versus D²PAK While Lowering Conduction and Switching Losses to Increase Efficiency

To provide higher efficiency and power density for telecom, industrial, and computing applications, Vishay Intertechnology, Inc. today introduced its first fourth-generation 600 V E Series power MOSFET in the new PowerPAK 8 x 8LR package. Compared to previous-generation devices, the Vishay Siliconix n- channel SiHR080N60E slashes on-resistance by 27 % and resistance times gate charge, a key figure of merit (FOM) for 600 V MOSFETs used in power conversion applications, by 60 % while providing higher current in a smaller footprint than devices in the D²PAK package.

Vishay offers a broad line of MOSFET technologies that support all stages of the power conversion process, from high voltage inputs to the low voltage outputs required to power the latest high tech equipment. With the SiHR080N60E and other devices in the fourth-generation 600 V E Series family, the company is addressing the need for efficiency and power density improvements in two of the first stages of the power system architecture — power factor correction (PFC) and subsequent DC/DC converter blocks. Typical applications will include servers, edge computing, super computers, and data storage; UPS; high intensity discharge (HID) lamps and fluorescent ballast lighting; telecom SMPS; solar inverters; welding equipment; induction heating; motor drives; and battery chargers.

Measuring 10.42 mm by 8 mm by 1.65 mm, the SiHR080N60E’s compact PowerPAK 8 x 8LR package features a 50.8 % smaller footprint than the D²PAK while offering a 66 % lower height. Due to its top-side cooling, the package delivers excellent thermal capability, with an extremely low junction to case (drain) thermal resistance of 0.25 °C/W. This allows for 46 % higher current than the D²PAK at the same on-resistance level, enabling dramatically higher power density. In addition, the package’s gullwing leads provide excellent temperature cycle capability.

Built on Vishay’s latest energy-efficient E Series superjunction technology, the SiHR080N60E features low typical on-resistance of 0.074 Ω at 10 V and ultra low gate charge down to 42 nC. The resulting FOM is an industry-low 3.1 Ω*nC, which translates into reduced conduction and switching losses to save energy and increase efficiency in power systems > 2 kW. For improved switching performance in hard-switched topologies such as PFC, half-bridge, and two-switch forward designs, the MOSFET released today provides low typical effective output capacitances Co(er) and Co(tr) of 79 pF and 499 pF, respectively. The package also provides a Kelvin connection for improved switching efficiency.

The device is RoHS-compliant and halogen-free, and it is designed to withstand overvoltage transients in avalanche mode with guaranteed limits through 100 % UIS testing.

Samples and production quantities of the SiHR080N60E are available now. For lead time information, please contact your local sales office.

The post Vishay Intertechnology 600 V E Series Power MOSFET in Compact Top-Side Cooling PowerPAK® 8 x 8LR Delivers Industry’s Lowest RDS(ON)*Qg FOM appeared first on ELE Times.

Optimize IoT Device Battery Life with Emulation and Profiling Software

Internet of things (IoT) devices have many uses in consumer, medical, and industrial areas. With more IoT devices coming to market, battery duration becomes essential for product quality and customer satisfaction. Their safety depends on battery performance for many of these applications, such as implantable medical devices. When the expected battery life does not meet real-world requirements, the device can become very dangerous for patients.

Battery life requirements are also high for intelligent city or asset-tracking applications. A smart meter in every home or a small asset tracker in every item will need a long-lasting battery, as changing batteries over a large deployment area is not profitable. Therefore, testing and predicting a device’s battery life is more important than ever.

With battery emulation and profiling software, device designers can estimate battery life precisely. Moreover, emulation software can evaluate current drain to modify device designs that can extend battery duration.

Importance of battery profiling softwareBatteries are nonideal energy sources because they interact with the device, influencing the current drain of the battery. Precise current consumption results are crucial for maximizing a device’s battery life. Consider the battery’s features when using a DC source to power the device to ensure that the current consumption results correctly imitate the battery current consumption.

There are several reasons why battery profiling and characterization are essential. Users must know how much energy the battery can hold and deliver as it drains over time. The open circuit voltage (VOC) and internal resistance (IR) change as the battery drains. These need to be plotted so that the battery profiles show the actual performance of the battery in the real world. Figure 1 shows a typical plot example of a battery profile.

Verifying the battery’s performance under certain discharge conditions and operating modes is also essential. Factors that influence battery behavior are:

- Temperature

- Load current profiles (constant/dynamic)

- Different operating modes, including constant current, power, and resistance

Battery life depends on these parameters, so making different battery profiles that suit specific discharge situations is essential.

A general-purpose DC source aims to be a perfect voltage source with no output impedance by using remote sensing feedback to maintain its output voltage constant. However, unlike a battery, its voltage does not decrease with load current. Moreover, feedback regulation is not instantaneous, which causes voltage drop and overshoot when loading and unloading changes. A significant transient voltage drop can activate a device’s low-battery-voltage shutdown.

When powering a device with a DC source, emulate the battery’s characteristics for current drain results comparable to those of a battery. A regular DC source differs from a battery, but a DC source that can imitate a battery helps users get more reliable results. Make sure the power supply used has a programmable output resistance.

Extending battery life with emulation softwareUsing a battery emulator instead of a battery has several advantages for device testing:

- Creates a safer test environment: By using an emulator, designers do not have to physically charge and discharge batteries, which can become dangerous with repeated cycles.

- Achieves repeatable results: Characteristics of an emulated battery do not vary from physical batteries, whose characteristics can fluctuate after charging / discharging. They can also vary between different batteries, even in the same model.

- Reduces test setup times: Designers can instantly simulate any state of charge (SoC) versus manually draining a battery to the desired level to speed testing.

A battery emulator operates through several steps. The initial step is to load a battery profile. This profile is the data from a graph of the battery voltage and internal resistance against the SoC, as shown in Figure 1. Designers can generate a battery profile using battery modeling software or get a profile from a battery provider.

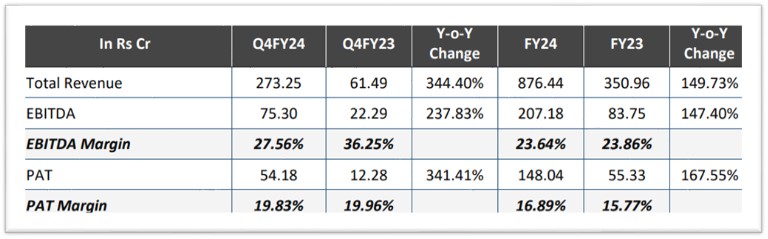

Creating a profile with modeling software will make the profile match the current consumption for a particular device, which is more precise than a generic profile from a battery supplier. For instance, a generic profile is not helpful if the battery supplier makes the profile based on a steady current draw when the device under test has a variable current consumption. Figure 2 shows a battery profiler with a current consumption profile from a device loaded into it. The software repeats the waveform until the battery runs out of power.

Figure 2. Example of a device’s current consumption waveform loaded into an advanced battery test and emulation software.

Figure 2. Example of a device’s current consumption waveform loaded into an advanced battery test and emulation software.

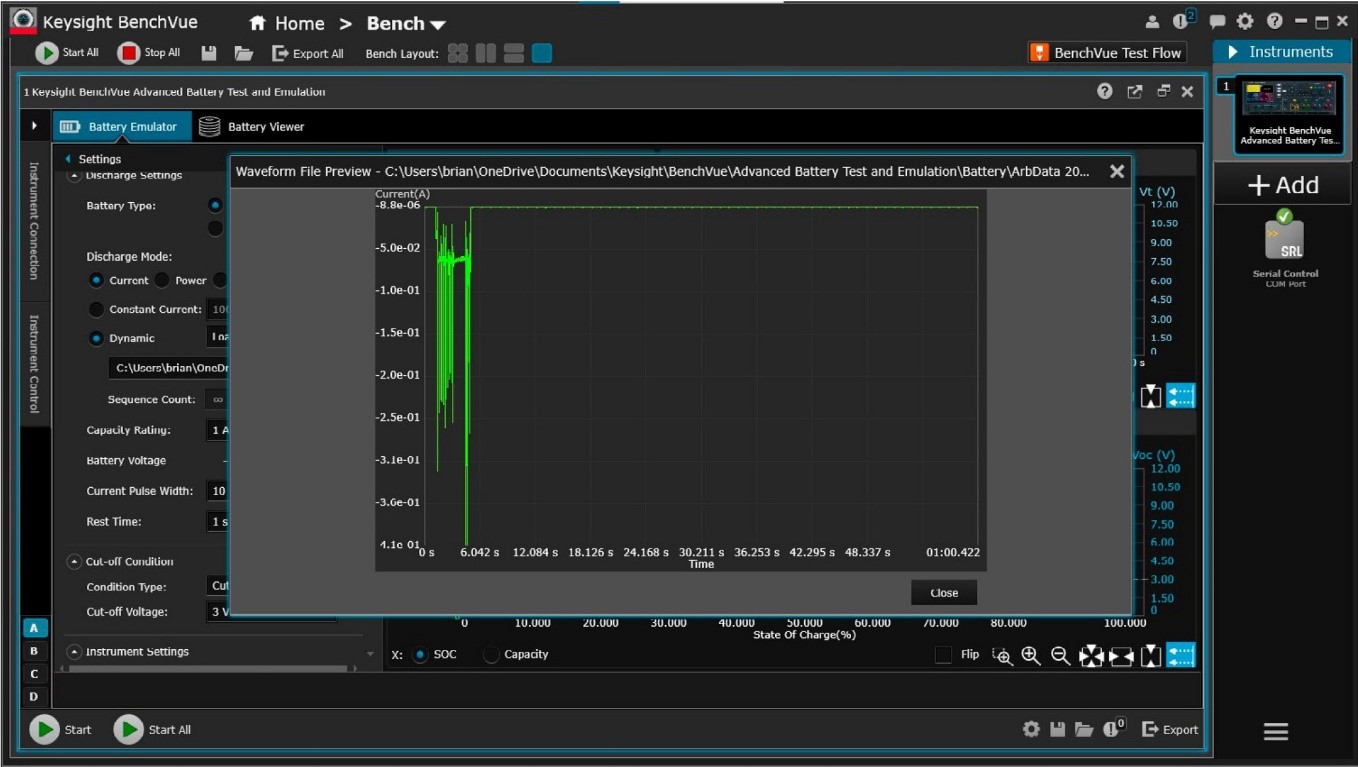

The next step is to choose the initial SoC and the termination voltage. Designers will link the device to the emulator and begin the battery emulation with software. Battery emulators constantly monitor the current, whether charging or discharging, to dynamically compute the emulated SoC. The emulator continually adjusts its output (voltage and resistance) according to the SoC to match the loaded battery profile. The test finishes when the emulator reaches the termination voltage if the emulator discharges.

Figure 3. Example of a device’s battery emulation using advanced battery test and emulation software.

Figure 3. Example of a device’s battery emulation using advanced battery test and emulation software.

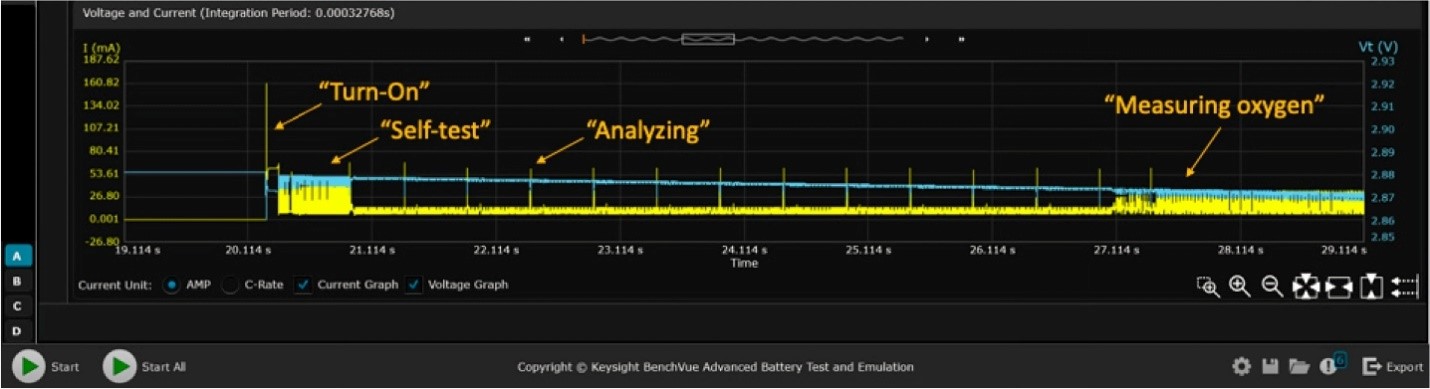

Designers can learn more about a device’s behavior by quickly emulating a battery at various SoCs. Figure 4 shows the information engineers can obtain from a device’s current drain. Engineers can use the data from this analysis to modify the design of the IoT device to improve battery performance.

Figure 4. Current drain analysis of a pulse oximeter medical IoT device using advanced battery test and emulation software.

Cycling battery charge/ discharge to determine capacity loss

Figure 4. Current drain analysis of a pulse oximeter medical IoT device using advanced battery test and emulation software.

Cycling battery charge/ discharge to determine capacity loss

Engineers need to know the energy a battery can store and deliver to IoT devices. Battery test and emulation software helps visually monitor battery charging and discharging to measure capacity. Software must support constant current (CC) and voltage (CV) modes for charging batteries. When the battery is nearly full using CC mode, the software must switch from CC mode to a mix of CC and CV. This mix is needed because a battery cannot be charged at the same rate when it reaches maximum voltage or capacity.

It is also crucial for the software to support constant current, constant resistance, and continuous power modes when discharging a battery. Engineers can use software to test and emulate current consumption profiles directly from a device. This feature allows engineers to quickly discharge the battery with a profile matching the current drain during usage. Running it throughout the rundown test and simulating it using the actual device to analyze the battery drain is simpler.

Battery performance can deteriorate significantly over a lifetime of charging and discharging. That is why it is essential to simulate battery cycling. Battery test and emulation software is a convenient solution, but the software must support data logging. Also, generating different charging and discharging profiles for a battery is very useful in a battery test and emulation software solution.

Designers can mix various charging and discharging sequences to simulate complex charging and discharging cycling profiles. Then, they can measure how a battery’s performance declines over time. Emulation software solutions are ideal for this as they can enable, for example, up to one thousand cycle operations to assess the battery’s aging effect and reliability under sequence test conditions.

SummaryBattery profiling and emulation software are essential for IoT device power analysis. They help improve battery life, mimic any charge and battery profile state, create more reliable and consistent test environments, and measure capacity loss and aging effects. This is important for product quality, customer satisfaction, and safety in various consumer, medical, and industrial applications.

The software ensures engineers do not have to charge and discharge batteries, which can become dangerous with repeated cycles—instantly simulating any state of charge versus manually draining a battery to the desired level. Battery software helps create a safer test environment, measures accurate, repeatable results, and reduces test setup times.

Andrew Herrera, Product Marketing Manager – Keysight Technologies

Andrew Herrera, Product Marketing Manager – Keysight Technologies

The post Optimize IoT Device Battery Life with Emulation and Profiling Software appeared first on ELE Times.

Research explores the effects of nuclear magnetic resonance on internal clock of cells

Wolfspeed quarterly revenue hit by weak industrial and energy markets

Cancel thermal airflow sensor PSRR with just two resistors

Self-heated transistors used as thermal air flow sensors are a particular (obsessive?) interest of mine, and over the years I must have designed dozens of variations on this theme. Figure 1 illustrates one such topology seen here before. It connects two transistors in a Darlington pair with Q2 serving as an unheated ambient thermometer and Q1 as the self-heated airflow sensor. Reference amplifier A1 and current sense resistor R3 regulate a constant 67 mA = heating current = 333 mW @ 5 V heating power.

Figure 1 Typical self-heated transistor thermal airflow sensor.

Wow the engineering world with your unique design: Design Ideas Submission Guide

This heat input raises Q1’s temperature above ambient by 64oC at 0 fpm air speed, cooling to 24oC at 1000 fpm as shown in Figure 2.

Figure 2 Thermal sensor temperature versus air speed.

As shown in Figure 2, the relationship between the airspeed and cooling of the self-heated transistor sensor is highly nonlinear. This is an inherent characteristic of such sensors and causes the sensor temperature versus air speed signal to be equally nonlinear. Consequently, even relatively small power supply instabilities, that translate % for % into instability in sensor temperature rise, can create surprisingly large airspeed measurement errors.

Clearly, anything less than perfect power supply stability can make this a problem.

But Figure 3 offers a surprisingly simple and inexpensive fix consisting of just two added resistors: R7 and R8.

Figure 3 Added R7 and R8 establish an instability-cancelling relationship between heating voltage V and heating current I.

The added Rs sum feedback from current sensing R3 with heating voltage source V. Summation happens in a ratio such that a percentage increase in V produces an equal and opposite percentage decrease in current I, and vice versa. The result is shown graphically in Figure 4.

Note the null (inflection) point at 5 V where heating is perfectly independent of voltage.

Figure 4: Sensor temperature versus supply voltage where: Blue = heating voltage V and (uncorrected) power; Red = heating current I; and Black = I*V = heating power / temperature.

Here’s the same thing in simple nullification math:

I = (0.2 – V*R8/R7)/R3 = (0.2 – 0.02V)/R3

H = I*V = (0.2V – 0.02V2)/R3

dH/dV = (0.2 – 0.04V)/R3 = (0.2 – 0.2)/R3 = 0 @ V = 5 volts

dH = -0.01% @ V = 5 volts ±1%

Note the 200:1 stability improvement that attenuates a ±1% variation in V down to only -0.01% variation in heating power and therefore temperature.

Problem solved. Cheaply!

Stephen Woodward’s relationship with EDN’s DI column goes back quite a long way. Over 100 submissions have been accepted since his first contribution back in 1974.

Related Content

- Self-heated Darlington transistor pair comprises new air flow sensor

- Nonlinearities of Darlington airflow sensor and VFC compensate each other

- Adding one resistor improves anemometer analog linearity to better than +/-0.5%

- Transistor linearly digitizes airflow

- A groovy apparatus for calibrating miniature high sensitivity anemometers

- 1kHz per Kelvin temperature sensor

The post Cancel thermal airflow sensor PSRR with just two resistors appeared first on EDN.

Is Rohm closer to acquiring Toshiba’s power chip business?

As Rohm Semiconductor deepens its ties with Toshiba Electronic Devices & Storage, industry watchers wonder if Rohm is getting closer to acquiring Toshiba’s power chips business. It all began late last year when the two companies announced a joint investment of $2.7 billion to collaborate on manufacturing power electronics devices.

But what made this news more noteworthy was that the announcement followed Rohm’s becoming part of a private equity group that was planning to take Toshiba private. However, when the two companies joined hands to boost the volume production of power devices, they stated that they had been considering this collaboration for some time and that it wasn’t a starting point in Rohm acquiring Toshiba’s power semiconductors business.

There is a third player in this $2.7 billion investment plan: the Japanese government, which adds another dimension to this hookup between Rohm and Toshiba Electronic Devices & Storage. Japan, aiming to strengthen the resilience of its semiconductor supply chains, recognises the strategic importance of power electronics and wants to double the power chip production in the country.

Moreover, Japan sees the local power chip industry as too fragmented, which makes it hard for them to compete with companies like Infineon. So, the Japanese government will subsidize one-third of this $2.7 billion investment in power semiconductor production on part of Rohm and Toshiba.

A closer look at this dimension also adds merits to the possibility of Rohm subsequently acquiring Toshiba’s power semiconductors business. It’s worth mentioning that Rohm was the first company to mass produce silicon carbide (SiC) MOSFETs, and it’s been continuously investing in this wideband gap (WBG) technology since then.

Figure 1 The Miyazaki Plant No. 2, based on assets acquired from Solar Frontier in July 2023, is dedicated to manufacturing SiC power devices. Source: Rohm

In the $2.7 billion joint investment plan announced late last year, Rohm will invest ¥289.2 billion in its new plant in Kunitomi, Miyazaki Prefecture, to produce SiC power chips. Toshiba will invest ¥99.1 billion in its newly built 300-mm fab in Nomi, Ishikawa Prefecture, to produce silicon-based power chips.

After delisting late last year, Toshiba faces an uncertain future. However, it still possesses highly valuable assets, and its power electronics business is one of them. There has also been chatter about splitting Toshiba into three units.

Figure 2 Vehicle electrification and automation of industrial equipment have led to strong demand for power devices like MOSFETs and IGBTs at 300-mm fab in Nomi. Source: Toshiba

When you see this potential divesture in the wake Japan’s desire to have a power electronics company that can compete with the likes of Infineon, Rohm taking over Toshiba’s power semiconductors business seems like a no-brainer. Among Japan’s current power chip firms, Rohm is known to have a stable power electronics business.

And the company is keen to affirm its management vision: “We focus on power and analog solutions and solve social problems by contributing to our customers’ needs for energy savings and miniaturization of their products.” Given this backdrop, Rohm taking over Toshiba Electronic Devices & Storage is probably a matter of time.

Related Content

- Toshiba is at crossroads, again

- New Rohm Fab Will Add Capacity for SiC Devices

- Zhenghai Group, Rohm Form JV for SiC Innovations

- Toshiba to spin off San Jose MPU engineering division

- Toshiba’s moment of semiconductor truth nears with upcoming split

The post Is Rohm closer to acquiring Toshiba’s power chip business? appeared first on EDN.

Waaree Renewable Technologies Limited Q4 results FY24

- Record Year of Strong Growth

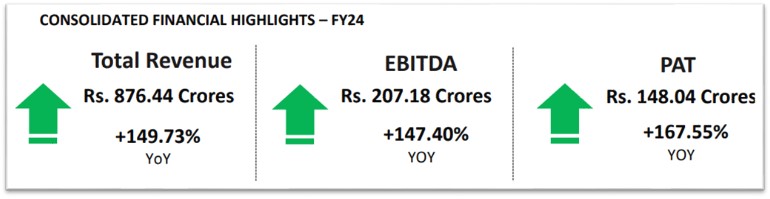

- Record Revenue growth of 149.73% YoY at Rs. 876.44 crores and Record PAT growth of 167.55% YoY at Rs. 148.04 crores

- Unexecuted Orderbook of 2,365 MWp to be executed in next 18 months

Waaree Renewable Technologies Limited, the Solar EPC subsidiary of Waaree Group, a solar developer that finances, constructs, owns and operates solar projects, has reported its audited financial results for the quarter and nine month ended March 31, 2024.

KEY PERFORMANCE HIGHLIGHTSFY24

- Revenue for FY24 stood at Rs. 876.44 crores representing a growth of 149.73% YoY as compared to Rs.350.96 crores in FY23

- EBITDA for FY24 stood at Rs. 207.18 crores as compared to Rs. 83.75 crores in FY23 representing a growth of 147.40% YoY

- PAT for FY24 stood at Rs. 148.04 crores as compared to Rs. 55.33 crores in FY23 representing a growth of 167.55% YoY

Q4FY24

- Revenue for Q4FY24 stood at Rs. 273.25 crores representing a growth of 344.40% YoY as compared to Rs. 61.49 crores in Q4FY23

- EBITDA for Q4FY24 stood at Rs. 75.30 crores as compared to Rs. 22.29 crores in Q4FY23 representing a growth of 237.83% YoY

- PAT for Q4FY24 stood at Rs. 54.18 crores as compared to Rs. 12.28 crores in Q4FY23 representing a growth of 341.41% YoY

Order book Position:

- Unexecuted order book stands at 2,365 MWp

- Bidding pipeline remains robust

Key Updates:

- The Company has successfully completed the corporate action of a stock split, reducing the face value of its Equity shares in the ratio of 1:5 per share. The face value of shares now stands at Rs. 2/- per share

- Recent Order Wins

- 980 MWp Ground Mounted solar power project

- 412 MWp Ground Mounted solar power project

- 450 MWp Ground Mounted Solar power Project

- 4 MWp Ground Mounted solar power project

Commenting on the results Mr. Dilip Panjwani, CFO, Waaree Renewable Technologies Limited said: “As a company committed to driving sustainable solutions, we are excited to share our progress and the significant opportunities that lie ahead. India has set an ambitious target to reduce the carbon intensity of the nation’s economy by less than 45% by the end of the decade, achieve 50 percent cumulative electric power installed by 2030 from renewables, and achieve net-zero carbon emissions by 2070. The country aims for 500 GW of renewable energy installed capacity by 2030.

The country’s renewable energy market is on the rise, with a record 69GW of bids in FY2024, surpassing the government’s target. Solar power, both grid-scale and rooftop, remains the primary contributor, accounting for 81% of the added capacity. The installed solar energy capacity has increased by 30 times in the last 9 years and stands at 81.81 GW as of March 2024.

Policy initiatives like the PM Surya Ghar: Muft Bijli Yojana aim to further boost solar installations, particularly in residential areas. With a strong balance sheet and disciplined financial management, the focus is on executing profitable projects with higher returns. This progress signifies not only environmental strides but also promising economic prospects in India’s renewable energy landscape.

We are also pleased to inform you that the board of directors has recommended a dividend of Rs. 1/- for the face value of share of Rs. 2/- each. With a sound balance sheet and disciplined capital management, we are well-equipped for the next phase of growth. We also would like to extend our gratitude to stakeholders for their continued trust and support.”

The post Waaree Renewable Technologies Limited Q4 results FY24 appeared first on ELE Times.

I built a WS2812 flower

| My first attempt at something freeform. A couple of WS2812 controlled by a small esp32 board. The feet are connected to capacitive touch sensors to control on/off, color mode and brightness. [link] [comments] |

Broken UHF Radio

| Ear piece no longer works on my radio after I went to the ground and landed on it causing the metal ring to come out. Radio still works fine just not with an ear piece. What would I have to do to go about fixing this? [link] [comments] |

Weekly discussion, complaint, and rant thread

Open to anything, including discussions, complaints, and rants.

Sub rules do not apply, so don't bother reporting incivility, off-topic, or spam.

Reddit-wide rules do apply.

To see the newest posts, sort the comments by "new" (instead of "best" or "top").

[link] [comments]

EEVblog 1614 - Circuit Design TIP: Crystal Oscillators

CSconnected appoints Howard Rupprecht as new managing director

India Gears Up to Celebrate National Technology Day 2024

India celebrated its first National Technology Day on May 11, 1999, after the successful nuclear test at Pokhran in 1998, to commemorate the many achievements of the Indian scientific and technology fraternity. This day serves as a testament to India’s constant and relentless pursuit of excellence and innovation. It is an opportunity to celebrate and honor the collaborative efforts of scientists, engineers, entrepreneurs, and educators, towards building a better, more efficient, and supportive innovation ecosystem.

It goes without saying that behind every technological breakthrough are countless individuals and organizations working tirelessly to break the glass ceiling and achieve the unfathomable. Hence, National Technology Day reminds the Indian community to keep investing in research and development, further cementing a culture of science and innovation while ensuring equitable access to technology for all.

India’s Story in Building a Strategic Scientific and Technology ForumThe journey of technology and innovation has been nothing short of exceptional for India. The nation has been a treasure trove of knowledge from the very start of civilization. With a rich scientific heritage dating back thousands of years, India, to begin with, has made significant contributions including the concept of zero, the formulation of algebra and trigonometry, and the decimal system. Aryabhatta is considered to be a major early physicist and a mathematician who explicitly developed theories on the motion of planets.

Indian scientific community has made great advancements in the fields of medicine, astronomy, engineering, space, biotechnology, renewable energy, electronics, automotive, and defence. The government has put sincere efforts into establishing refined, top-notch, and highly competitive educational facilities like the Indian Institute of Technology (IITs) and Indian Institutes of Science (IISc) among others. Also, to bolster the R&D ecosystem in the country, institutions like the Council of Scientific and Industrial Research (CSIR) and the Indian Space Research Organization (ISRO) have been established.

The Indian IT industry is booming to become a global hub with MNCs like Tata Consultancy Services, Wipro, and Infosys playing a crucial role in accelerating the nation’s economic growth. The Space program has achieved significant milestones, including the launch of satellites, lunar exploration missions (Chandrayaan-1 and Chandrayaan-2), and Mars exploration (Mangalyaan).

The story doesn’t end here; India is also among the top players in biotechnology and pharmaceuticals, with rapid development in areas like vaccine development, generic drug manufacturing, and biotech research. Also, the country is investing hugely in renewable energy stressing on adopting environment-friendly ways and technology in the long run.

How far has India Come?India in the last decade has seen major strides in the field of science and technology on a global level. Initiatives like “Make in India” launched by the GoI in 2014 aim at transforming the nation into a global manufacturing hub by attracting foreign investments, improving the ease of doing business, and promoting skill development, to revitalize the manufacturing sector and promote economic growth and job creation in the country. “Digital India” is another initiative launched with the vision of transforming India into a digitally-enabled and empowered society. It aims at leveraging digital technologies to bridge the digital divide and promote growth and development in varied sectors like electronics, automotive, IT, transportation, and communication.

With such initiatives being actively worked upon, India has been hit by the wave of startup culture. The EV sector is ramping up with denser infra being set up across the country. Technology leaders like Tesla and TATA are making their way in the EV segment in India. The country is boosting its semiconductor business with GoI investing bulk in setting up manufacturing units. We also saw mobile phone manufacturing jump 21 times to nearly Rs. 4.1 lakh Cr in the last 10 years.

Industry Speaks:Read with us what top thought leaders have to say as we observe National Technology Day this year.

Mr. Aalok Kumar, Corporate Officer & Sr. VP – Head of the Global Smart City Business at NEC Corporation and President & CEO at NEC Corporation India

“Over the past decade, India has matured into global leadership in technological innovation. This has altered how we experience how the day-to-day services are provided and above all, how citizens utilize civic services. This transformation is fundamentally underpinned by the recognition of technology’s potential to change lives and communities for the better. Today, India is on a steady path to realizing its vision for a ‘Viksit Bharat’ by 2047, and the role of technology comes into sharp focus with greater responsibility than ever before. At this juncture, the tech innovation ethos in India is evolving to “purposeful innovation” aimed at societal good, demanding creative and responsible application of AI, ML, and big data analytics to solve day-to-day problems of the common man.

At NEC India, our purpose is to build technology that serves the people, and as intelligent communities emerge, driven by data analytics and AI, we are proud to be playing our part in shaping a future where technology redefines citizen-centricity in civic services empowering lives. India’s unique position as a rapidly urbanizing nation undergoing large-scale digital transformation presents an unparalleled opportunity as a testing ground for innovative solutions that can be adapted to various markets worldwide.”

Mr. Sivakumar Selva Ganapathy, Vice President at OpenBlue India Software Engineering & APAC Solutions, Johnson Controls

“This year, India celebrates the 25th anniversary of National Technology Day. As we reflect on this journey, it is evident that our progress over the past two decades has been nothing short of remarkable. From our early achievements to emerging as a global technological hub today, India’s strength and capability in the domain speaks for itself.

While technology has impacted every sector in India, one area where it is poised to make a defining impact is sustainability. From building management systems analyzing occupancy patterns to AI-powered Smart grids optimizing energy distribution, technology is actively transforming cities into efficient and sustainable hubs. As a corollary, the area of green technology and green buildings is increasingly becoming more relevant, and as it continues to evolve, skilling & curriculum development assumes added importance. It is our firm belief that this can be best achieved through industry-academia collaboration.

At Johnson Controls India, we are observing a steady increase in the adoption of technologies for green buildings, and it won’t be long before buildings evolve from merely being smart, to autonomous – capable of governing and maintaining itself! This National Technology Day, as we look at the strides made, we also look forward to witnessing the future of green technologies unfold, and renew our commitment to innovating for a green tomorrow. “

The Way Forward for India India holds tremendous potential for innovation and collaboration in varied sectors including healthcare, education, transportation, and communication, where technology has permeated and unlocked new opportunities for growth and development.

India holds tremendous potential for innovation and collaboration in varied sectors including healthcare, education, transportation, and communication, where technology has permeated and unlocked new opportunities for growth and development.

National Technology Day is not merely about gadgets and gizmos but holds a more profound implication on how technology has impacted our society for the better. Technology has the power to democratize access to information, improve healthcare systems, enhance education, foster economic development, and promote sustainable development.

As we commemorate this day in 2024, let us look at the future with optimism and resolve and reaffirm our commitment to leverage the power of technology responsibly and ethically, to create a more inclusive and sustainable world.

The post India Gears Up to Celebrate National Technology Day 2024 appeared first on ELE Times.

How Wi-Fi sensing simplifies presence detection

The emerging technology of Wi-Fi sensing promises significant benefits for a variety of embedded and edge systems. Using only the radio signals already generated by Wi-Fi interfaces under normal operation, Wi-Fi sensing can theoretically enable an embedded device to detect the presence of humans, estimate their motion, approximate their location, and even sense gestures and subtle movements, such as breathing and heartbeats.

Smart home, entertainment, security, and safety systems can all benefit from this ability. For example, a small sensor in a car could detect the presence of back-seat passengers—soon to be a requirement in new passenger vehicles. It can even detect a child breathing under a blanket as it does not require line of sight. Or an inexpensive wireless monitor in a home could detect in a room or through walls when a person falls—a lifesaver in home-care situations.

Figure 1 Wi-Fi Sensing can be performed on any Wi-Fi-enabled device with the right balance of power consumption and processing performance. Source: Synaptics

Until recently, such sensing could only be done with a passive RF receiver relying on the processing capability of a nearby Wi-Fi access point. Now, it can be done on every Wi-Fi-enabled end device. This article explores how designers can get from theory to shipped product.

How it works

The elegance of Wi-Fi sensing is that it uses what’s already there: the RF signals that Wi-Fi devices use to communicate. In principle, a Wi-Fi receiving device could detect changes in those RF signals as it receives them and, from the changes, infer the presence, motion, and location of a human in the area around the receiver.

Early attempts to do this used the Wi-Fi interface’s receive signal strength indicator (RSSI), a number produced by the interface periodically to indicate the average received signal strength. In much the same way that a passive infrared motion detector interprets a change in IR intensity as motion near its sensor, these Wi-Fi sensors interpret a change in RSSI value as the appearance or motion of an object near the receiver.

For instance, a person could block the signal by stepping between the receiver and the access point’s transmitter, or a passing person could alter the multipath mix arriving at the receiver.

RSSI is unstable in the real world, even when no one is nearby. It can be challenging to separate the influences of noise, transmitter gain changes, and many other sources from the actual appearance of a person.

This has led researchers to move to a richer, more frequently updated, and more stable data stream. With the advent of multiple antennas and many subcarrier frequencies, transmitters and receivers need far more information than just RSSI to optimize antenna use and subcarrier allocation. Their solution is to take advantage of channel state information (CSI) in the 802.11n standard. This should be available from any compliant receiver, though the accuracy may vary.

Figure 2 Wi-Fi system-on-chips (SoCs) can analyze CSI for subtle changes in the channel through which the signal is propagating to detect presence, motion, and gestures. Source: Synaptics

CSI is reported by the receiver every time a subcarrier is activated. It is essentially a matrix of complex numbers, each element conveying magnitude and phase for one combination of transmit and receive antennas. A three-transmit-antenna, two-receive-antenna channel would be a 3 x 2 array. The receiver generates a new matrix for each subcarrier activation. So, in total, the receiver maintains a matrix for each active subcarrier.

The CSI captures far more information than the RSSI, including attenuation and phase shift for each path and frequency. In principle, all this data contains a wealth of information about the environment around the transmitter and receiver. In practice, technical papers have reported accurate inference of human test subjects’ presence, location, motion, and gestures by analyzing changes in the CSI.

Capturing presence data

Any compliant Wi-Fi interface should produce the CSI data stream. That part is easy. However, it is the job of the sensor system to process the data and make inferences from it. This process is generally divided into three stages, following the conventions developed for video image processing: data preparation, feature extraction, and classification.

The first challenge is data preparation. While the CSI is far more stable than the RSSI, it’s still noisy, mainly due to interference from nearby transmitters. The trick is to remove the noise without smoothing away the sometimes-subtle changes in magnitude or phase that the next stage will depend upon to extract features. But how to do this depends on the extraction algorithms and, ultimately, the classification algorithms and what is being sensed.

Some preparation algorithms may simply lump the CSI data into time bins, toss out outliers, and look for changes in amplitude. Others may attempt to extract and amplify elusive changes in phase relationships across the subcarriers. So, data preparation can be anything from a simple time-series filter to a demanding statistical algorithm.

Analysis and inference

The next stage in the pipeline will analyze the cleansed data streams to extract features. This process is analogous—up to a point—to feature extraction in vision processing. In practice, it is quite different. Vision processing may, for instance, use simple numerical calculations on pixels to identify edges and surfaces in an image and then infer that a surface surrounded by edges is an object.

But Wi-Fi sensors are not working with images. They are getting streams of magnitude and phase data that are not related in any obvious way to the shapes of objects in the room. Wi-Fi sensors must extract features that are not images of objects but are instead anomalies in the data streams that are both persistent and correlated enough to indicate a significant change in the environment.

As a result, the extraction algorithms will not simply manipulate pixels but will instead perform complex statistical analysis. The output of the extraction stage will be a simplified representation of the CSI data, showing only anomalies that the algorithms determine to be significant features of the data.

The final stage in the pipeline is classification. This is where the Wi-Fi sensor attempts to interpret the anomaly reported by the extraction stage. Interpretation may be a simple binary decision: is there a person in the room now? Is the person standing or sitting? Are they falling?

Or it may be a more quantitative evaluation: where is the person? What is their velocity vector? Or it may be an almost qualitative judgment: is the person making a recognizable gesture? Are they breathing?

The nature of the decision will determine the classification algorithm. Usually, there is no obvious, predictable connection between a person standing in the room and the resulting shift in CSI data. So, developers must collect actual CSI data from test cases and then construct statistical models or reference templates, often called fingerprints. The classifier can then use these models or templates to best match the feature from the extractor and the known situations.

Another approach is machine learning (ML). Developers can feed extracted features and correct classifications of those features into a support vector machine or a deep-learning network, training the model to classify the abstract patterns of features correctly. Recent papers have suggested that this may be the most powerful way forward for classification, with reported accuracies from 90 to 100% on some classification problems.

Wi-Fi sensing implementation

Implementing the front-end of an embedded Wi-Fi sensing device is straightforward. All that’s required is an 802.11n-compliant interface to provide accurate CSI data. The back-end is more challenging as it requires a trade-off between power consumption and capability.

For the data preparation stage, simple filtering may be within the range of a small CPU core. After all, a small matrix arrives only when a subcarrier is activated. But more sophisticated, statistical algorithms will call for a low-power DSP core. The statistical techniques for feature extraction are also likely to need the power and efficiency of the DSP.

Classification is another matter. All reported approaches are easily implemented in the cloud, but that is of little help for an isolated embedded sensor or even an edge device that must limit its upstream bandwidth to conserve energy.

Looking at the trajectory of algorithms, from fingerprint matching to hidden Markov models to support vector machines and deep-learning networks, the trend suggests that future systems will increasingly depend on low-power deep-learning inference accelerator cores. Thus, the Wi-Fi sensing system-on-chip (SoC) may well include a CPU, a DSP, and an inference accelerator.

However, as this architecture becomes more apparent, we see an irony. Wi-Fi sensing’s advantage over other sensing techniques is its elegant conceptual simplicity. But something else becomes clear as we unveil the true complexity of turning the twinkling shifts in CSI into accurate inferences.

Bringing a successful Wi-Fi sensing device to market will require a close partnership with an SoC developer with the right low-power IP, design experience, and intimate knowledge of the algorithms—present and emerging. Choosing a development partner may be one of the most important of the many decisions developers must make.

Ananda Roy is senior product line manager for wireless connectivity at Synaptics.

Related Content

- Going the Distance With Wi-Fi HaLow

- Exploring the superior capabilities of Wi-Fi 7 over Wi-Fi 6

- Paving the Way to Ambient-Powered Wireless Connectivity

- WIRELESS/RF: SenSiFi WiFi sensor module promises battery life of 3+ years

- Blocking 6-GHz Wi-Fi Is Costing Consumers Money and Quality Experiences

The post How Wi-Fi sensing simplifies presence detection appeared first on EDN.

Handheld analyzers gain pulse generator option

FieldFox handheld RF analyzers from Keysight can now generate an array of pulse types at frequencies as high as 54 GHz. Outfitted with Option 357 pulse generator software, the FieldFox B- and C-Series analyzers give field engineers access to pulse generation capabilities that support analog modulations and user-defined pulse sequences. All that is needed to upgrade an existing analyzer is a software license key and firmware upgrade.

The software option includes standard pulses, FM chirps, FM triangles, AM pulses, and user-definable pulse sequences. In addition, it can create continuous wave (CW) signals with or without AM/FM modulations, including frequency shift keying (FSK) and binary phase shift keying (BPSK). Key parameters of the generated signal are displayed in both numerical and graphical formats.

FieldFox handheld analyzers equipped with pulse generation serve many purposes, including field radar testing for air traffic control, simulating automotive radar scenarios, performing field EMI leakage checks, and assessing propagation loss of mobile networks.

Find more datasheets on products like this one at Datasheets.com, searchable by category, part #, description, manufacturer, and more.

The post Handheld analyzers gain pulse generator option appeared first on EDN.

Software platform streamlines factory automation

Reducing shop-floor hardware, Siemens’ Simatic Automation Workstation delivers centralized software-defined factory automation and control. The system allows manufacturers to replace a hardware programmable logic controller (PLC), conventional human-machine interface (HMI), and edge device with a single software-based workstation.

Hundreds of PLCs can be found throughout plants, each one requiring extensive programming to keep it up-to-date, secure, and aligned with other PLCs in the manufacturing environment. In contrast, the Simatic Workstation can be viewed and managed from a central point. Since programming, updates, and patches can be deployed to the entire fleet in parallel, the shop floor remains in synch.

Simatic Workstation is an on-premise operational technology (OT) platform. It offers high data throughput and low latency, essential for running various modular applications. Simatic caters to conventional automation tasks, like motion control and sequencing, as well as advanced automation operations that incorporate artificial intelligence.

The Simatic Automation Workstation is the latest addition to Siemens’ Xcelerator digital business platform. Co-creator Ford Motor Company will be the first customer to deploy and scale these workstations across its manufacturing operations.

Find more datasheets on products like this one at Datasheets.com, searchable by category, part #, description, manufacturer, and more.

The post Software platform streamlines factory automation appeared first on EDN.

Silicon capacitor boasts ultra-low ESL

Joining Empower’s family of E-CAP silicon capacitors for high-frequency decoupling is the EC1005P, a device with an equivalent series inductance (ESL) of just 1 picohenry (pH). The EC1005P offers a capacitance of 16.6 µF, along with low impedance up to 1 GHz. A very thin profile allows the capacitor to be embedded into the substrate or interposer of any SoC, especially those used in high-performance computing (HPC) and artificial intelligence (AI) applications.

E-CAP high-density silicon capacitor technology fulfills the ‘last inch’ decoupling gap from the voltage regulators to the SoC supply pins. This approach integrates multiple discrete components into a single monolithic device with a much smaller footprint and component count than solutions based on conventional multilayer ceramic capacitors.

In addition to sub-1-pH ESL, the EC1005P provides sub-3-mΩ equivalent series resistance (ESR). The capacitor comes in a 3.643×3.036-mm, 120-pad chip-scale package. Its standard profile of 784 µm can be customized for various height requirements.

The EC1005P E-CAP is sampling now, with volume production expected in Q4 2024. A datasheet for the EC1005P was not available at the time of this announcement. For more information about Empower’s ECAP product family, click here.

Find more datasheets on products like this one at Datasheets.com, searchable by category, part #, description, manufacturer, and more.

The post Silicon capacitor boasts ultra-low ESL appeared first on EDN.